Jaw Crusher Machine components often fail due to poor lubrication, improper installation, and overloading. Routine maintenance and selecting quality casting material, such as manganese steel plate, can extend Jaw Crusher Parts service life by up to 25%. Using reliable Crusher Parts ensures better performance and reduces unexpected breakdowns.

Key Takeaways

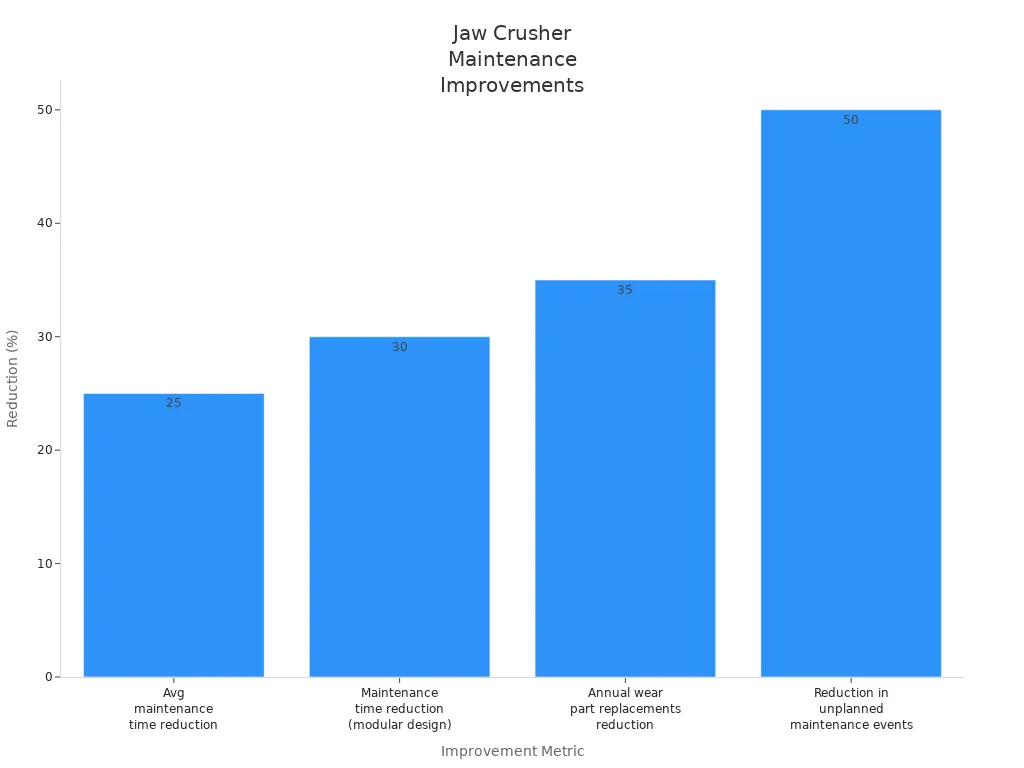

- Perform daily inspections and routine maintenance to catch problems early and keep the jaw crusher running smoothly, which can extend part life by up to 30%.

- Use proper lubrication with the right oils and greases to reduce wear and prevent damage, ensuring parts last longer and the machine operates efficiently.

- Choose high-quality, original equipment manufacturer (OEM) parts and manage feed material carefully to reduce wear, lower downtime, and save on maintenance costs.

Jaw Crusher Machine Maintenance and Operation

Routine and Preventive Maintenance

Routine and preventive maintenance play a vital role in keeping a Jaw Crusher Machine running smoothly. Equipment manufacturers recommend daily visual inspections during operation. Operators should check flywheels and flywheel weights for movement or looseness. They must inspect jaw die bolts, fasteners, toggle plates, and toggle seat areas for proper placement and tightness. Greasing the Pitman and main frame bearings according to factory guidelines is essential. Drive V-belt tension should be checked every day. Listening for unusual noises helps detect mechanical issues early. Operators should monitor hydraulic pressure or electrical amp gauges to spot obstructions or problems. Maintaining the flywheel RPM within factory ranges ensures optimal crushing power. Periodic checks of the Pitman assembly for movement on the main shaft are necessary. Jaw dies should be inspected for uneven wear, and operators should adjust feed methods or flip dies to maximize their life. Side liners or cheek plates must be checked and replaced regularly to protect the main frame.

Tip: Creating a maintenance checklist helps operators remember each step and ensures nothing gets overlooked.

Common challenges during maintenance include premature bearing failures from insufficient inspections, improper management of wear parts, and running parts beyond their useful life. Heat, humidity, dust, and wildlife can also affect the machine. Ignoring diagnostic displays or warning indicators can lead to bigger failures. Operators should always allow the equipment to cool down before shutting it off to prevent thermal stress.

Proper Lubrication Practices

Proper lubrication is critical for reducing wear and extending the life of Jaw Crusher Machine parts. Lubricants must match the needs of each component. Oils work best for high-speed, high-temperature, and high-pressure parts like bearings and gears. Greases are better for low-speed, low-temperature, and low-pressure parts such as bushings, pins, and slides.

| Lubricant Type | Characteristics and Advantages | Recommended Applications in Jaw Crushers |

|---|---|---|

| Oils | Flow easily, cool and remove contaminants, need regular maintenance | Bearings, gears, eccentric shafts |

| Greases | Stay in place, seal and protect, reduce noise and vibration | Bushings, pins, chains, slides |

Manufacturers recommend using No. 70 oil for high outdoor temperatures and No. 50 oil for moderate conditions. In winter, preheating oil is necessary. Grease should be applied to bushings and toggle plates every 3-4 hours. The oil return temperature should stay below 60°C, and water cooling may be needed for some parts.

Note: Insufficient lubrication is a leading cause of bearing wear. Without enough lubricant, friction increases, causing severe wear and even shaft fractures if the oil contains water.

Signs of inadequate lubrication include unusual sounds, vibrations, overheating, increased power consumption, and oil leaks. Operators should regularly check lubricant levels and quality, replace lubricants as recommended, and ensure all lubrication points receive attention. Environmental factors like dust and cold weather can affect lubrication. In harsh environments, greases with high base oil viscosity help maintain film thickness and protect against wear.

Fastener and Structural Checks

Fastener and structural checks ensure the Jaw Crusher Machine remains safe and reliable. Monthly inspections should include the frame, foundation, jaws, liners, toggle plates, bearings, drive shafts, belts, pulleys, and sheaves. Operators must look for cracks, distortion, loose bolts, wear, and alignment issues. Documentation of wear patterns helps track component condition over time.

| Issue Category | Specific Problems Identified | Causes/Notes | Recommended Actions |

|---|---|---|---|

| Fastening screws | Loose or broken screws of lining and toothed plates | Metal collision sounds, lining plate shaking | Replace or tighten screws promptly |

| Pulley/Flywheel keys | Damage or looseness | Flywheel swing, eccentric shaft rotation issues | Tighten or replace keys |

| Springs and compression nuts | Looseness or damage | Impact sounds, instability | Tighten nuts, replace springs |

| Elbow plates and sliders | Wear or breakage | Collision noises, immediate replacement if broken | Replace worn or broken parts |

| Bearing shells | Looseness or damage | Bearing temperature rise, malfunction | Adjust compression, add or replace oil |

| Adjustment mechanisms | Wedge-shaped top base displacement, adjustment seat defects | Material transportation issues | Pull wedge base backward, replace/tighten screws |

| Structural components | Fractured jaws, broken toggle plates, bent or broken eccentric shafts | Overload, improper installation, wear | Replace damaged parts, ensure proper installation |

Operators should use calibrated torque wrenches to check bolt tightness and inspect the foundation for stability. If structural issues are found, they must adjust or replace parts as needed. For example, they should replace worn or broken jaw plates, springs, or liners promptly. After major repairs, a no-load trial run ensures smooth operation.

Correct Operation and Training

Correct operation and proper training help reduce wear and extend the life of the Jaw Crusher Machine. Operator training programs teach safe loading techniques, how to recognize warning signs, and how to adjust machine settings. Training also covers troubleshooting and equipment functionalities. Regular refresher courses keep operators updated on new technology and safety protocols.

Training workers to perform maintenance and inspections enables early problem detection, saving parts and reducing wear.

Operators should use the correct feed size and ensure even material distribution. They must rotate or flip jaw plates regularly to distribute wear. Lubricating toggle bearings and maintaining proper tension reduces mechanical stress. Installing protective liners helps shield surrounding components. Operators should avoid running plates past wear limits and feeding oversized or unsorted material.

Following safety protocols, such as turning off and locking out the machine during maintenance, reduces the risk of injuries and equipment damage. Pre-shift inspections, monitoring start-up parameters, and logging bearing temperatures help detect issues early. Proper use of the Jaw Crusher Machine by trained operators leads to longer service life and fewer breakdowns.

Jaw Crusher Machine Parts and Material Management

Use of Quality Spare Parts

Selecting high-quality spare parts is essential for maintaining the performance and longevity of a Jaw Crusher Machine. Reliable spare parts, especially those made by the original equipment manufacturer (OEM), offer several advantages:

- OEM parts match exact specifications and use high-strength materials.

- These parts undergo advanced manufacturing and strict quality control.

- OEM parts fit perfectly and maintain system compatibility.

- They withstand harsh conditions, reducing the risk of premature failure.

- Rigorous testing ensures durability and reliability.

Aftermarket parts may not always meet these standards. They often use lower-quality materials and have less precise tolerances, which can lead to increased wear and more frequent replacements. Using OEM parts, although sometimes more expensive upfront, results in fewer breakdowns and lower maintenance costs over time.

| Benefit Aspect | Impact on Jaw Crusher Maintenance and Operation |

|---|---|

| Maintenance Cost Savings | Up to 20% reduction annually by optimizing performance |

| Component Lifespan | Extended by up to 30%, reducing replacement frequency |

| Downtime Reduction | Decreased by up to 30%, minimizing operational interruptions |

| Wear Resistance | Improved, leading to fewer replacements and breakdowns |

| Fit and Durability | Enhanced, maintaining crushing efficiency and reducing disruptions |

| Overall Effect | Lower maintenance expenses and increased productivity |

High-quality spare parts also provide accurate dimensions, ensuring proper fit and function. This reduces downtime and helps maintain optimal crushing efficiency. Companies that use strong, wear-resistant parts report cost savings of 40-60% due to fewer replacements and longer part life.

Tip: Always verify supplier certifications, request material composition reports, and choose parts made from durable materials like manganese steel or alloy steel.

Material Feed Management

Proper material feed management plays a key role in extending the service life of Jaw Crusher Machine parts. The characteristics of the feed material—such as hardness, abrasiveness, particle size, and moisture content—directly affect wear rates and machine efficiency.

- Hard materials like granite or quartzite cause more wear on jaw plates and liners.

- Abrasive minerals scratch and grind surfaces, accelerating metal loss.

- Oversized rocks concentrate impact on certain areas, leading to uneven wear.

- High moisture or sticky materials can clog the crusher, increasing stress and wear.

Operators can follow these best practices to manage material feed:

- Use a feeder or scalping screen to ensure smooth material flow and prevent clogging.

- Keep the crushing chamber at least 80% full for efficient operation.

- Remove material larger than 80% of the crusher opening to avoid blockages.

- Pre-screen the feed to remove fines that cause extra wear.

- Provide a well-graded feed for consistent crushing and reduced part wear.

- Avoid feeding lightweight or sticky materials that can build up on jaw plates.

- Limit metal debris in the feed to prevent damage and downtime.

Matching jaw plate materials and designs to the feed characteristics, along with regular inspections, helps reduce wear and extend part life. Consistent and even feeding prevents blockages and maximizes the efficiency of the Jaw Crusher Machine.

Note: Monitoring feed size and hardness allows operators to adjust crusher settings and select the right wear parts, further improving durability.

Partnering with Experts

Consulting with industry experts and manufacturers brings significant benefits for Jaw Crusher Machine maintenance and operation. Experts provide guidance on daily maintenance routines, troubleshooting, and selecting the right spare parts. Their support helps operators detect wear early, schedule preventive maintenance, and avoid major failures.

- Regular inspections by experts identify wear and tear before it becomes severe.

- Preventive maintenance schedules keep equipment running within specifications.

- Access to skilled technicians ensures rapid diagnosis and repair, reducing downtime.

- Expert advice on shutdown planning and workflow optimization improves efficiency.

- Training from experts enhances safety and operational knowledge for staff.

Case studies show that expert consultations can reduce maintenance time from 8 hours to less than 2 hours per week. Upgrading to advanced models with expert guidance can increase production efficiency by 20% and extend the service life of critical components by about 30%. Companies also benefit from improved safety, better planning, and cost savings through energy efficiency and optimized wear part management.

Callout: Building a relationship with a trusted service provider ensures ongoing support, access to the latest technology, and tailored solutions for unique operational needs.

Partnering with experts helps operators implement best practices, maximize equipment uptime, and achieve long-term reliability for their Jaw Crusher Machine.

Consistent care for the Jaw Crusher Machine leads to longer part life and fewer breakdowns. Companies that follow maintenance routines, use quality parts, and train operators see up to 50% less downtime.

| Maintenance Practice | Lifespan Improvement |

|---|---|

| Regular inspections | 30% longer part life |

| Scheduled lubrication | 25% less downtime |

| Use of wear-resistant parts | 35% fewer replacements |

FAQ

What materials work best for jaw crusher parts?

High manganese steel, high chromium cast iron, and alloy steel provide strong wear resistance. These materials help jaw crusher parts last longer in tough working conditions.

How often should operators inspect jaw crusher parts?

Operators should inspect critical parts daily. They should also perform a more detailed inspection every month to catch early signs of wear or damage.

Why is proper lubrication important for jaw crusher machines?

Proper lubrication reduces friction and heat. This helps prevent early wear and keeps the machine running smoothly. Regular checks keep all moving parts protected.

Post time: Jul-24-2025